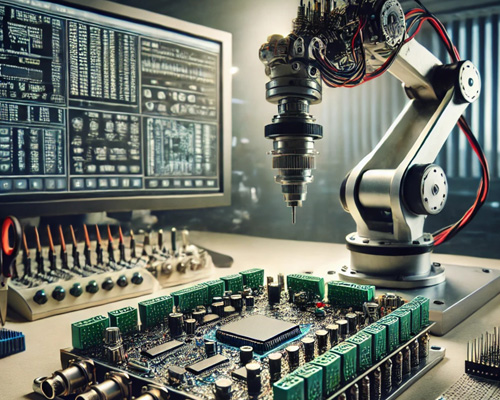

Precision Stepper

Motor Controller

A high-accuracy multi-axis stepper motor controller engineered for robotic arm applications, featuring microstepping, closed-loop feedback, and real-time trajectory planning.

A high-accuracy multi-axis stepper motor controller engineered for robotic arm applications, featuring microstepping, closed-loop feedback, and real-time trajectory planning.

TMC2209 stepper drivers with StealthChop and SpreadCycle for silent, high-torque operation

STM32F4 MCU running real-time motion planning with interrupt-driven step generation

Optical encoders and limit switches for closed-loop position verification and homing

G-code interpreter with custom trajectory planner and web-based jog control interface

256 microstep resolution achieving 0.01mm positional accuracy with anti-backlash compensation on all axes.

Coordinated 6-axis interpolation with S-curve acceleration profiles for smooth and jerk-free robotic movements.

Look-ahead trajectory planner processing up to 1000 motion segments per second with velocity smoothing.

StealthChop drive mode reduces motor noise to near-silent levels while maintaining full torque at low speeds.

Optical encoder feedback detects missed steps and automatically corrects position drift without stopping operation.

Hardware limit switches, software boundaries, emergency stop, and thermal protection for safe unattended operation.

Joint range-of-motion specification, torque calculations, and motor selection for each axis of the robotic arm.

Custom carrier board for TMC2209 drivers with current sensing, thermal management, and EMI shielding.

STM32 firmware with real-time step generation, G-code parsing, and closed-loop PID position control.

Forward and inverse kinematics solver for Cartesian-to-joint-space conversion with collision detection.

Full system validation with repeatability testing, load characterization, and long-duration endurance runs.

From CNC machines to robotic arms, our team designs custom motor control solutions that deliver uncompromising accuracy and reliability.